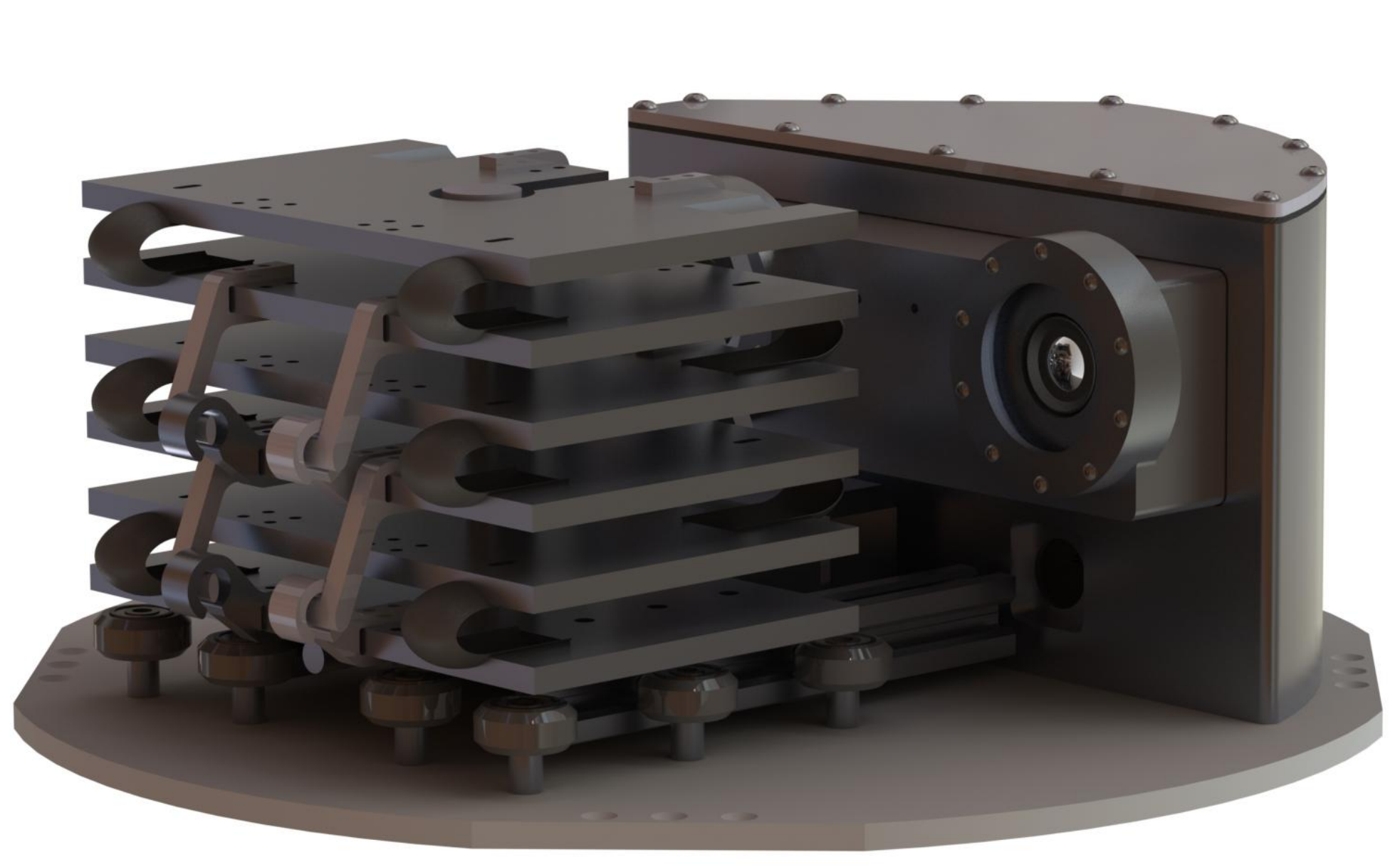

One of the final CAD assemblies of our experiment. We were provided a mounting plate that stacked with other projects on the second stage of the sounding rocket.

Here is a slow-motion video of a test deployment from Summer 2019.

We machined the flight-ready mock panels by hand on a manual mill.

We built a more sophisticated gravity offload system in order to do better testing on the aluminum panels. Long strings are attached to the ceiling with springs in series to minimize extraneous forces acting on the panels, while providing offload.

We were forced to outsource the manufacturing of our electronics housing, along with some other components due to the pandemic.

Pretty close to the final mechanical assembly. Electronics hadn't yet been integrated at this point.

One of the final deployment tests.

About this project

The goal of this project was to demonstrate the ability to passively deploy solar panels for future satellites and spacecraft. By using high-energy tape springs (Stanley tape measure), our mock solar array deploys without the need for any motors, actuators or other complex electromechanical systems. We collaborated with a local company ROCCOR (now Redwire Space) who specialize in composites and deployable structures for space systems.

COVID put a huge damper on this project, delaying launch for a year and preventing us from collaborating together in person. In the end we did get the project completed and it was launched from Wallops Flight Facility. Unfortunately due to an electrical problem, the cameras didn't record the deployment at apogee. It appears that the panels deployed successfully and ejected themselves from the rocket, but it's impossible to know exactly how it went.